SV-101 PPTA-PULP

SV-101 PPTA-PULP is a high-tech short fiber material independently developed and produced by Hebei Silicon Valley Chemical Co.,Ltd. Due to the wide application of aramid pulp,it has also been developed rapidly. Our company uses Silicon Valley fiber as raw material to produce aramid pulp,and has formed a high-tech aramid pulp,and has formed a high-tech aramid pulp production line with an annual output of 500 tons. The product can be used in relevant friction and sealing industries to replace asbestos to make non asbestos products.

Our company’s aramid pulp performance index has exceeded the international advanced level,and won the trust and trial of customers with high quality and good price. The company also specializes in production according to the needs of customers to meet the needs of customers in various fields.

It’s our lofty responsibility to provide the society with professional,high starting point,high quality and high-tech products and services.

Changes to the PPTA-PULP

Aramid pulp fiber has the same excellent physical and mechanical properties,so as an ideal substitute for asbestos fiber,it’s widely used in the field of friction and sealing materials. As early as the mid-1900s,Europe、America and other regions carried out the environmental protection campaign to ban the use of asbestos,which led to the rapid development of aramid pulp. In 1996,the world sales volume was 9000 tons,accounting for about 40% of total aramid fiber. It takes a great market.

Aramid pulp is mainly used as asbestos substitute fiber in the friction materials,such as clutch lining,brake pad. It can effectively use its high strength,excellent heat resistance and friction performance. It has higher energy absorption function and lower density than asbestos,so the product has light weight,less wear to coupling parts,stable friction coefficient and 2-3 times of asbestos products. It’s very popular with friction material manufacturers. As a reinforcing filler in sealing materials, pulp can improve the pressure resistance and corrosion resistance of sealing gasket, which is applied in high-tech field. Pulp can also be used to make high-grade synthetic paper, insulating paper and resin with high breakdown voltage and high temperature resistance can be laminated into thin printed circuit board, etc.

Product Characteristic

SV-101 aramid pulp is a kind of aramid staple fiber product made from para aramid staple fiber (poly-p-phenylene terephthamide, PPTA, Fanglun 1414) by special process flow.

Aramid pulp has high strength, high modulus, small shrinkage rate, high temperature resistance, corrosion resistance, high voltage resistance, good insulation, stable chemical properties, large surface area and other excellent properties.

The aramid pulp has rich surface hairiness and large specific surface area after raw fiber processing. The specific surface area of short fiber cut by aramid filament is 0.5-0.8 m2/g, while that of aramid pulp is 6-18 m2/g. It has good compatibility with resin, rubber and other substrates.

Application Range

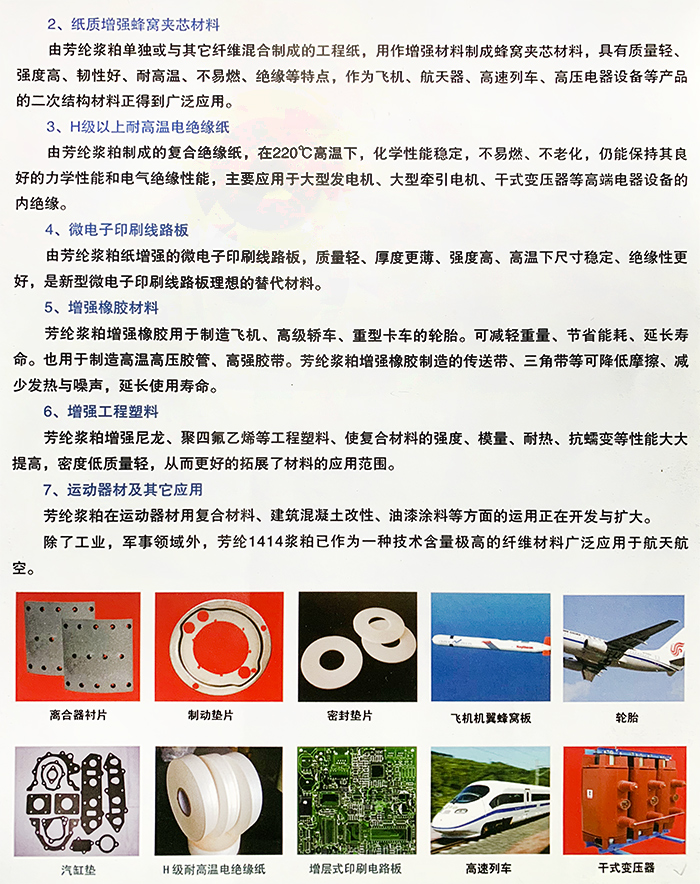

1. Making friction and sealing materials instead of asbestos

The strength of aramid pulp is 5-6 times that of high quality steel, the modulus is 2-3 times that of steel, the toughness is twice that of steel, and the weight is only 1/5 of steel. It can be used normally for a long time from -196-204℃. Its shrinkage is 0 at 150℃ and doesn’t decompose or melt at 560℃. Used for making high performance products such as aircraft, high speed train, automobile brake pad, clutch lining, sealing gasket,etc. It can replace asbestos containing carcinogens.

With the development of aramid pulp industry technology, it is widely used in the field of friction and sealing materials.

2. Paper reinforced honeycomb core material

The engineering paper made from aramid pulp or mixed with other fibers is used as reinforcing material to make honeycomb core material. It has the characteristics of light weight, high strength, good toughness, high temperature resistance, nonflammable, insulation and so on. It is widely used as the secondary structure material of aircraft, spacecraft, high-speed train, high-voltage electrical equipment and other products.

3. High temperature resistant electrical insulating paper above grade H

The composite insulation paper made of aramid pulp has stable chemical properties, non flammability and non aging at 220 ℃, and can still maintain its good mechanical properties and electrical insulation properties. It is mainly used for internal insulation of high-end electrical equipment such as large generators, large traction motors and dry-type transformers.

4. Microelectronic printed circuit board

The microelectronic printed circuit board reinforced by aramid pulp paper has the advantages of light weight, thinner thickness, high strength, dimensional stability at high temperature and better insulation. It is an ideal substitute for new micro electronic printed circuit board.

5. Reinforced rubber material

Aramid pulp reinforced rubber is used to make tires for airplanes, limousine and heavy trucks. It can reduce weight, save energy consumption and prolong service life. It is also used to manufacture high temperature and high pressure hose and high strength adhesive tape. The conveyor belt and triangle belt made of aramid pulp reinforced rubber can reduce friction, heat and noise, and extend service life.

6. Reinforced engineering plastics

Aramid pulp reinforce nylon, PTFE and other engineering plastics can greatly improved their strength, modulus, heat resistance, creep resistance and other properties of the composite material, made low density and light weight, so as to better expand the application range of the materials.

7. Sports equipment and other applications

The application of aramid pulp in composite materials for sports equipment, modification of building concrete, paints and coatings is being developed and expanded.

In addition to the industrial and military fields, aramid 1414 pulp has been widely used in aerospace industry as a fiber material with high technical content.